Introduction: Why Pipe Material Choice Matters in Plumbing

Whether you’re a DIY enthusiast tackling a bathroom renovation or a seasoned plumbing professional, the selection of pipe materials is one of the most critical decisions you’ll make. Each plumbing pipe—copper, PEX, CPVC, PVC, galvanized steel, and others—offers unique advantages and drawbacks in terms of performance, durability, installation ease, and overall cost. The right choice can mean decades of leak-free service, lower maintenance, and savings; the wrong one can result in premature failures, frustrating repairs, and unnecessary expenses.

In this comprehensive guide, we’ll pit the most common residential and light commercial pipe materials against each other. You’ll learn not only which pipe is best for specific applications (hot water lines, main supply, drain lines, etc.), but also get a breakdown of longevity, resistance to freezing, corrosion, installation difficulty, and how each material affects your budget. We’ll also cover evolving industry preferences and touch on eco-friendliness, so you can make an informed, future-proof choice for your next plumbing project.

Overview of Common Plumbing Pipe Materials

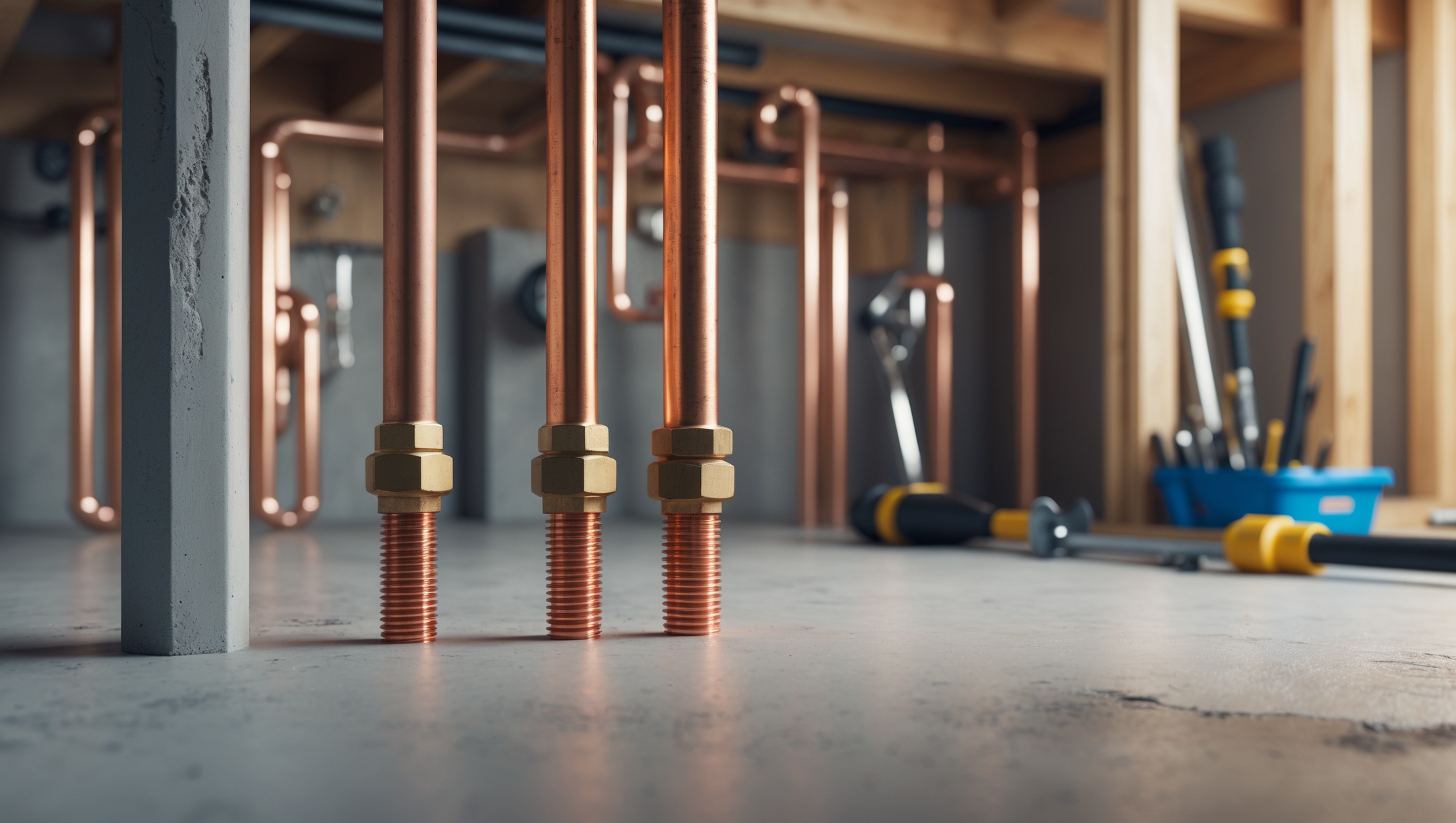

Copper Pipe

Overview: Copper has been the gold standard for plumbing for over a century, prized for its reliability and proven longevity. Available in rigid (Type L, M, K) and flexible forms, copper’s popularity has only recently been challenged by newer materials.

- Uses: Hot and cold potable water, refrigerant lines, hydronic heating.

- Available Sizes: 1/4″ to 2″ common for residential use.

- Joining Methods: Soldering (sweating), press-fit, compression, push-fit.

PEX (Crosslinked Polyethylene)

Overview: PEX has rapidly gained ground due to its flexibility, ease of installation, and resistance to scale and chlorine. It’s available in red (hot), blue (cold), and white (universal) colors for easy identification.

- Uses: Potable water supply, radiant heating systems, remodeling.

- Available Sizes: 3/8″ to 1″ for most residential applications.

- Joining Methods: Crimp, clamp, push-fit, expansion fittings.

CPVC (Chlorinated Polyvinyl Chloride)

Overview: CPVC is a plastic pipe designed for hot and cold water supply. It’s similar to PVC but withstands higher temperatures, making it suitable for domestic hot water lines.

- Uses: Hot and cold potable water, fire sprinkler systems.

- Available Sizes: 1/2″ to 2″ common in homes.

- Joining Methods: Solvent cement welding.

PVC (Polyvinyl Chloride)

Overview: PVC is a stalwart for drain, waste, and vent (DWV) piping. While not rated for hot water supply, it excels in non-pressurized and cold water applications.

- Uses: Drainage, waste, venting, irrigation.

- Available Sizes: 1 1/2″ to 4″ (and larger) for DWV.

- Joining Methods: Solvent cement welding, threaded fittings.

Galvanized Steel

Overview: Once the standard for water supply, galvanized steel is now primarily found in older homes. Corrosion and rust issues have led to its decline in new construction.

- Uses: Water supply (legacy), outdoor applications.

- Available Sizes: 1/2″ to 2″.

- Joining Methods: Threaded fittings.

Other Materials

- ABS: Used for DWV similar to PVC, black in color.

- Stainless Steel: Specialty use where corrosion is a concern, expensive.

- Polybutylene: Discontinued due to failure rates but sometimes encountered in homes built from the late 1970s to mid-1990s.

Performance and Durability: A Head-to-Head Comparison

Longevity

- Copper: 50–70 years or more with proper water chemistry.

- PEX: 40–50 years expected in typical conditions.

- CPVC: 40–50 years, but can become brittle with age.

- PVC: 50–100 years (for DWV, non-pressurized).

- Galvanized Steel: 20–50 years; inner corrosion reduces lifespan.

Resistance to Corrosion and Scaling

- Copper: Resists bacteria, but susceptible to acidic water and pinhole leaks in certain conditions.

- PEX: Immune to corrosion and scaling; unaffected by most water chemistries.

- CPVC/PVC: Non-corrosive, but can degrade with UV exposure (especially outdoors).

- Galvanized Steel: Highly prone to rust, scale buildup, and flow restriction over time.

Temperature and Pressure Ratings

- Copper: Excellent for hot and cold water, pressure-rated for all residential use.

- PEX: Withstands up to 200°F and 80 psi; suitable for most residential applications.

- CPVC: Rated up to 200°F; pressure rating decreases with temperature.

- PVC: Not for hot water (max 140°F), mainly for drain lines.

- Galvanized Steel: Handles high pressure but not recommended for hot water due to corrosion risk.

Freeze Resistance

- Copper: Will burst if water freezes inside. No flexibility.

- PEX: Expands and contracts, highly resistant to freeze-breakage.

- CPVC/PVC: Brittle when frozen; likely to crack or split.

- Galvanized Steel: Rigid, will burst if frozen.

Installation Ease: Labor and DIY Friendliness

Copper

Requires precise measuring, cutting, cleaning, and soldering (or press-fit fittings). While durable, it’s labor-intensive and has a steeper learning curve for beginners. Open flames (torches) introduce fire hazards. Repairs in tight spaces can be challenging.

PEX

Extremely flexible, allowing for long, continuous runs and easy routing around obstacles. Installation with crimp/clamp/expansion tools is fast and requires no torch. Ideal for remodels and retrofits, as it can be snaked through walls and joists. Push-fit fittings enable quick repairs, though they add cost.

CPVC

Cut with standard plastic pipe cutters or saws, joined with solvent cement. No heat or special tools required. Joints must be dry and clean for best results. Brittle nature makes it less suited for areas with movement or vibration.

PVC

Similar to CPVC but almost exclusively used for DWV (drainage) piping. Lightweight, easy to cut and fit. Solvent welding is straightforward but requires proper ventilation.

Galvanized Steel

Heavy, difficult to cut and thread, and prone to rusting tools. Installation is slow and laborious, requiring pipe wrenches and threading equipment. Rarely recommended for new DIY work.

Cost Breakdown: Material, Labor, and Long-Term Value

Material Costs (per 10 feet, 2024 average)

- Copper (Type L): $25–$35

- PEX: $5–$8

- CPVC: $7–$10

- PVC (DWV): $4–$6

- Galvanized Steel: $20–$30

Note: Fitting costs vary—copper and PEX push-fit fittings can be significantly more expensive than standard connections.

Labor Costs

- Copper: High. Skilled labor for soldering and tight clearances.

- PEX: Low. Fast installation offsets slightly higher fitting costs.

- CPVC/PVC: Moderate. Easy to cut and join, but must allow for curing time.

- Galvanized Steel: Very high. Labor-intensive and slow.

Long-Term Maintenance and Replacement

- Copper: Minimal if installed properly, but susceptible to water chemistry issues in some areas.

- PEX: Virtually maintenance-free, but some fittings and brands have had recall issues—choose reputable manufacturers.

- CPVC: Vulnerable to impact and aging; may require replacement after decades.

- Galvanized Steel: High maintenance; expect eventual replacement due to corrosion.

Environmental and Health Considerations

Water Quality and Taste

- Copper: Generally neutral, but acidic water can leach copper (rarely an issue at normal pH).

- PEX: Some brands may impart a slight taste/odor initially; certified products are safe for potable water.

- CPVC/PVC: No known taste; only use certified pipes for potable water.

- Galvanized Steel: Can impart a metallic taste and cause discoloration.

Recyclability and Eco-Friendliness

- Copper: 100% recyclable; high scrap value.

- PEX/CPVC/PVC: Difficult to recycle; most ends up in landfills.

- Galvanized Steel: Recyclable, but less commonly done.

Health and Safety Notes

- Always use pipes and fittings certified for potable water (look for NSF/ANSI 61 certification).

- Improper installation or use of non-potable-grade pipes can lead to contamination.

- Never use PVC for hot water supply—only for drains and vents.

Application Guide: Choosing the Right Pipe for the Job

Supply Lines (Hot and Cold Water)

- Best Choices: Copper, PEX, CPVC

- Considerations: PEX for ease and flexibility. Copper for longevity and reliability. CPVC if plastic is preferred and budget is limited.

Remodels and Retrofits

- Best Choice: PEX

- Reason: Flexibility allows routing through existing walls with minimal demolition.

Drain, Waste, and Vent (DWV)

- Best Choices: PVC, ABS

- Reason: Lightweight, cost-effective, and resistant to corrosion.

Outdoor and Specialty Applications

- Best Choices: Copper (with insulation), PEX (buried lines, with protective sleeves), stainless steel (where extreme corrosion is a concern).

Pros and Cons Table: At a Glance

| Material | Pros | Cons | Best For |

|---|---|---|---|

| Copper | Long lifespan, recyclable, proven reliability, resists bacteria | Expensive, labor-intensive, vulnerable to acidic water | Main supply, visible runs, high-value homes |

| PEX | Flexible, cost-effective, freeze-resistant, fast install | UV sensitive, can’t be used outdoors, lower scrap value | Retrofits, new builds, radiant heating |

| CPVC | Inexpensive, chemical-resistant, easy to install | Brittle over time, not for freezing climates | Budget supply lines, DIY upgrades |

| PVC | Low cost, corrosion-proof, easy to work with | Not for hot water, brittle in cold | Drain, waste, vent lines |

| Galvanized Steel | Strong, historically reliable | Heavy, rusts, hard to install, obsolete | Legacy repairs only |

Case Studies: Real-World Examples

Case Study 1: Full-Home Repiping in an Older Residence

An early-1960s home with failing galvanized steel was repiped using PEX. The installer was able to snake PEX through existing wall cavities, minimizing drywall damage and reducing labor time by 40%. Material costs were a third of copper, and all work passed inspection. The homeowner observed better water flow and no metallic taste.

Case Study 2: Copper in a High-End Remodel

For a luxury bathroom addition, copper was chosen for visible supply lines and shower fixtures. The project required skilled soldering but resulted in an elegant, professional finish. The higher upfront cost was justified by the expected lifespan and premium feel.

Case Study 3: CPVC in a Budget Kitchen Update

A DIYer replaced aging copper under a kitchen sink with CPVC due to its affordability and simple solvent welding. The job was completed with basic tools in a single afternoon. While not as durable as copper, the project met budget constraints and improved flow.

Maintenance and Troubleshooting Tips by Material

Copper

- Check for greenish corrosion spots, especially at joints.

- Address pinhole leaks promptly; they may indicate water chemistry issues.

- Drain system if soldering repairs are needed.

PEX

- Protect from direct sunlight (UV exposure).

- Inspect fittings for leaks after extreme temperature swings.

- Use manufacturer-recommended tools and connectors.

CPVC/PVC

- Check for brittleness or cracks, especially near fixtures or where exposed.

- Support long runs to prevent sagging and stress on joints.

- Avoid impact and overtightening of fittings.

Galvanized Steel

- Look for rust, discoloration, and reduced water flow.

- Replace sections showing advanced corrosion instead of patching.

Frequently Asked Questions

- Can I mix pipe materials in my plumbing system? Yes, but use approved transition fittings and check local codes for compatibility.

- Is PEX safe for drinking water? Yes, if it carries NSF/ANSI 61 certification.

- Can I use PVC for water supply lines? No, use only for drains and vents—never for pressurized potable water.

- What’s the best pipe for hard water areas? PEX or CPVC, as they resist scale buildup.

Conclusion: Making an Informed Choice for Long-Term Success

Choosing the right plumbing pipe material isn’t just a technical decision—it’s a critical investment in your home’s safety, efficiency, and value. Copper offers unmatched longevity and a time-tested reputation, but requires a higher upfront investment and professional skill. PEX brings flexibility, ease, and affordability to the table, making it the top choice for many modern homes and remodels. CPVC and PVC provide budget-friendly options for water supply and drainage, respectively, but come with their own caveats regarding impact resistance and temperature limits. Galvanized steel, while obsolete for new installations, serves as a cautionary tale about the importance of material evolution in the plumbing industry.

When planning your next plumbing project, weigh the pros and cons outlined in this guide. Consider your region’s climate, water chemistry, budget, and the expected lifespan of your installation. Don’t forget to check local codes, as some jurisdictions restrict certain materials for specific uses. Finally, invest in quality fittings and proper installation—no material, however advanced, can compensate for poor workmanship.

By understanding the strengths and weaknesses of each pipe material, you’ll be equipped to make smart, sustainable choices that keep your plumbing system running smoothly for decades to come. Whether you’re laying the foundation for a new home or tackling a long-overdue update, your pipe selection will shape the reliability and comfort of your living space for years ahead.

Andrew Lopez

I’m planning a bathroom renovation in an older home with some existing copper pipes, but I’m tempted by the easier installation of PEX for the new sections. Is it a good idea to mix the two, and are there any issues I should watch out for when connecting copper to PEX?