Introduction: Why Plumbing Tool Storage Matters

For every plumbing professional and serious DIY enthusiast, tools are more than just implements—they are essential partners on every job. However, without a system for storage and organization, even the best tools can become liabilities. Lost wrenches, damaged pipe cutters, and rusted threading tools cost time, money, and credibility. A cluttered workspace or van leads to wasted effort, increased risk of injury, and premature tool replacement. Conversely, a well-organized storage system boosts productivity, protects your investment, and ensures you are always ready for the next challenge. This comprehensive guide dives into practical, field-tested plumbing tool storage solutions—whether you work from a sprawling workshop, a compact garage, or a mobile van setup. Discover how to organize for maximum efficiency, prevent tool damage, and create a professional impression with clients and colleagues alike.

Assessing Your Plumbing Tool Inventory

Why Inventory Matters

Before reorganizing or investing in new storage, take stock of what you have. An accurate, up-to-date inventory prevents unnecessary purchases, highlights missing or duplicated items, and reveals what storage solutions you truly need. For business owners, it also aids insurance claims and tax documentation.

How to Conduct a Tool Audit

- Gather All Tools: Collect every tool from your workshop, van, and job sites. Don’t forget seldom-used specialty items.

- Sort by Category: Group hand tools, power tools, diagnostic equipment, consumables, and accessories separately.

- Document: Use a spreadsheet or tool management app to log each item, its condition, serial numbers, and storage location.

- Purge: Dispose of broken, obsolete, or duplicate tools responsibly.

Workshop Organization: Building a Functional Home Base

Layout Principles

A well-designed workspace saves steps and reduces search time. Start with a floor plan:

- Work Zones: Dedicate spaces for assembly, repairs, cleaning, and storage.

- Traffic Flow: Keep main walkways clear. Place frequently used tools within arm’s reach of your main bench.

- Vertical Storage: Use walls for racks, shelves, and pegboards to free up floor space.

Storage Types

- Pegboards and Slatwalls: Ideal for hanging wrenches, pliers, and pipe cutters. Use labeled outlines for quick identification and return.

- Drawer Cabinets: Store small items like washers, O-rings, and replacement valves in shallow, labeled drawers or divided organizer boxes.

- Shelving Units: Heavy-duty metal shelves hold toolboxes, power tools, and bulkier equipment. Adjustable shelves accommodate changing needs.

- Bins and Totes: Stackable bins are perfect for consumables—PVC fittings, copper elbows, Teflon tape—sorted by type and size.

- Magnetic Strips: Secure screwdrivers, snips, and other metal tools for instant access.

Climate and Security Considerations

- Humidity Control: Install a dehumidifier or moisture absorbers to prevent rust, especially for precision tools.

- Security: Invest in lockable cabinets or a monitored workshop alarm to deter theft.

Mobile Plumbing: Organizing Your Work Van

Why Van Organization is Different

On the road, space is at a premium and tools are exposed to vibration, temperature swings, and theft risks. A thoughtfully organized van turns every job into a smoother, faster process and projects professionalism to clients.

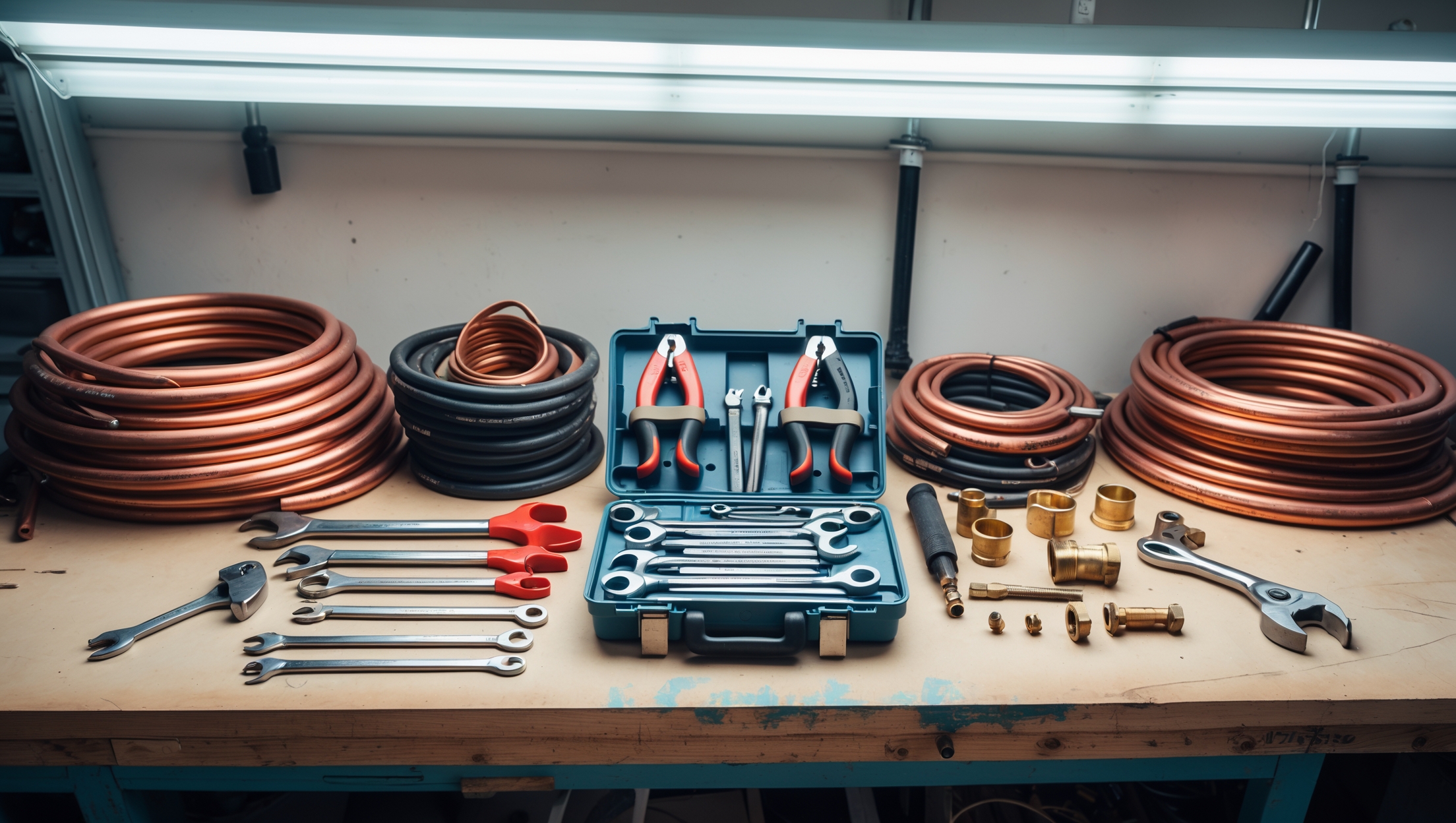

Essential Storage Solutions for Vans

- Custom Shelving Units: Install modular shelving tailored to your tool inventory. Include adjustable dividers for flexibility.

- Drawer Systems: Heavy-duty drawers keep small tools and parts secure and sorted. Lockable drawers deter theft.

- Tool Racks: Mount racks for pipe wrenches, levels, and tubing benders to prevent shifting during transit.

- Parts Organizers: Transparent bins with tight lids make it easy to spot and access fittings and fasteners.

- Pipe Storage Tubes: Secure PVC or metal tubes along the van’s length for safe, accessible pipe transport.

- Power Tool Cases: Keep drills, saws, and batteries in their original cases, stacked on shelves to minimize jostling.

Van Safety and Security

- Load Restraints: Use cargo straps or netting to prevent toolboxes from sliding.

- Weatherproofing: Ensure all storage is sealed against dust and moisture.

- Locks and Alarms: Upgrade van locks and consider GPS tracking for high-value equipment.

Tool Protection: Preventing Damage and Extending Lifespan

Cleanliness is Key

Dirty tools corrode faster and can damage other equipment in storage. Build quick cleaning into your routine:

- Wipe down hand tools after every job.

- Lubricate moving parts (pipe cutters, threading tools) regularly.

- Use compressed air to clear debris from power tools.

Rust Prevention

- Store tools in dry areas; use silica gel packs or vapor corrosion inhibitor (VCI) bags for added protection.

- Apply light machine oil to exposed metal surfaces.

- Never store wet tools—dry thoroughly after use.

Protective Cases and Foam Inserts

- For specialty tools (pipe inspection cameras, electronic leak detectors), invest in hard cases with custom foam inserts to absorb shocks and prevent scratches.

- Label cases for quick ID in the field.

DIY Storage Solutions: Budget-Friendly Options

Repurposing Materials

- PVC Pipe Racks: Cut short lengths of PVC pipe, mount them to a board, and use them for storing screwdrivers, chisels, and small hand tools.

- Magnetic Tool Bars: Affordable bars can be mounted anywhere for instant, visible storage.

- Old Cabinets: Repurpose kitchen cabinets as wall-mounted storage for larger tools.

Custom Rolling Carts

- Build or buy a sturdy cart with shelves, hooks, and bins to move essential tools between your workshop and vehicle.

- Include a pegboard panel for hanging commonly used items.

Labeling and Inventory Management

Label Everything

- Use color-coded labels or tags for different tool categories.

- Label drawers, bins, and shelves so anyone can find and return items quickly.

- Consider QR code labels linked to a digital inventory for larger businesses.

Inventory Apps and Digital Tools

- Apps like Sortly, ToolWatch, or even a shared Google Sheet help track tool locations, maintenance schedules, and usage history.

- Set reminders for calibrating diagnostic equipment or replacing consumables.

Tool Storage for Specialized Plumbing Equipment

Inspection Cameras and Electronics

- Always store in padded, waterproof cases.

- Remove batteries if storing for long periods to prevent corrosion.

- Keep silica gel packs inside cases to absorb moisture.

Threading and Pressing Tools

- Clean and lubricate after each use before storing in fitted cases.

- Hang heavy manual threaders on reinforced wall brackets to prevent accidental drops.

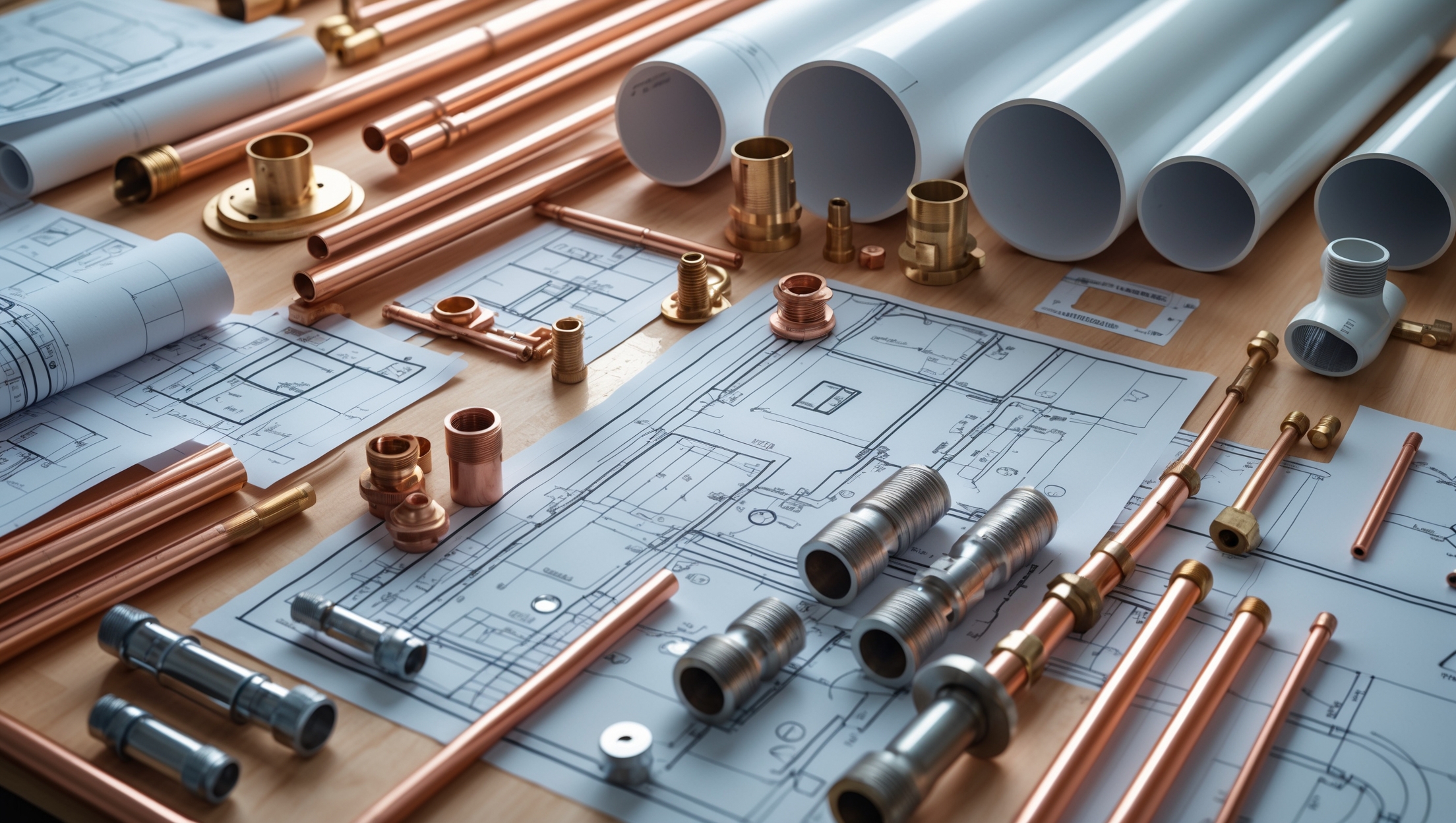

Consumables and Replacement Parts

- Use clear, divided organizers for O-rings, washers, and small valves.

- Label expiration dates for items like sealants and adhesives.

Best Practices for Maintenance and Routine Checks

- Schedule quarterly deep cleans of your main storage areas.

- Inspect storage units for rust, moisture, or pest damage.

- Rotate stock—use older consumables first to prevent waste.

- Replace worn foam inserts and tighten hardware on storage units regularly.

Professional Image: How Organized Storage Impresses Clients

First impressions matter. When clients see a plumber arrive with a tidy, organized van or witness a workshop where every tool has its place, confidence soars. Organized storage communicates reliability, attention to detail, and respect for both your tools and your client’s property. Even on hectic days, a solid storage system prevents embarrassing delays searching for tools or fumbling with tangled hoses. In competitive markets, this professionalism can be the deciding factor for repeat business and referrals.

Conclusion: Invest in Storage, Reap Professional Rewards

Effective plumbing tool storage is more than a matter of aesthetics—it’s a cornerstone of safety, efficiency, and professionalism. By assessing your inventory, optimizing your workspace or van, and maintaining a rigorous routine of cleaning, labeling, and digital tracking, you protect both your livelihood and your reputation. The upfront effort yields dividends: fewer lost tools, faster job completion, lower replacement costs, and a clear edge over less organized competitors. Whether you implement high-end modular systems or inventive DIY solutions, the goal is the same—every tool in its place, ready when you need it, and protected for years of dependable service. Start small, prioritize your most-used items, and build from there. Your future self—and your clients—will thank you for the investment in organization and care.

Patricia Hernandez

After I finish taking inventory and getting rid of duplicates like you suggest, what’s the best way to prevent my collection from getting cluttered again over time? Any habits or routines you recommend to keep things organized long-term?