Introduction: Why Every DIYer or Pro Needs a Dedicated Plumbing Workshop

Whether you’re an enthusiastic DIYer or a professional plumber working from home, a dedicated plumbing workshop can transform your approach to repairs, projects, and learning. Instead of searching for scattered tools or improvising on the kitchen floor, imagine having a space where every wrench, pipe, and fitting is in its place, safety is prioritized, and even large-scale projects feel manageable. Setting up your own home plumbing workshop isn’t just about convenience—it’s about efficiency, safety, and taking pride in your craft. In this guide, we’ll walk you through the essential steps to create a functional, organized, and safe plumbing workspace at home. From choosing the right space and planning the layout, to storage solutions, safety protocols, and even tips for handling hazardous materials, you’ll learn how to build a workshop that supports your plumbing ambitions for years to come.

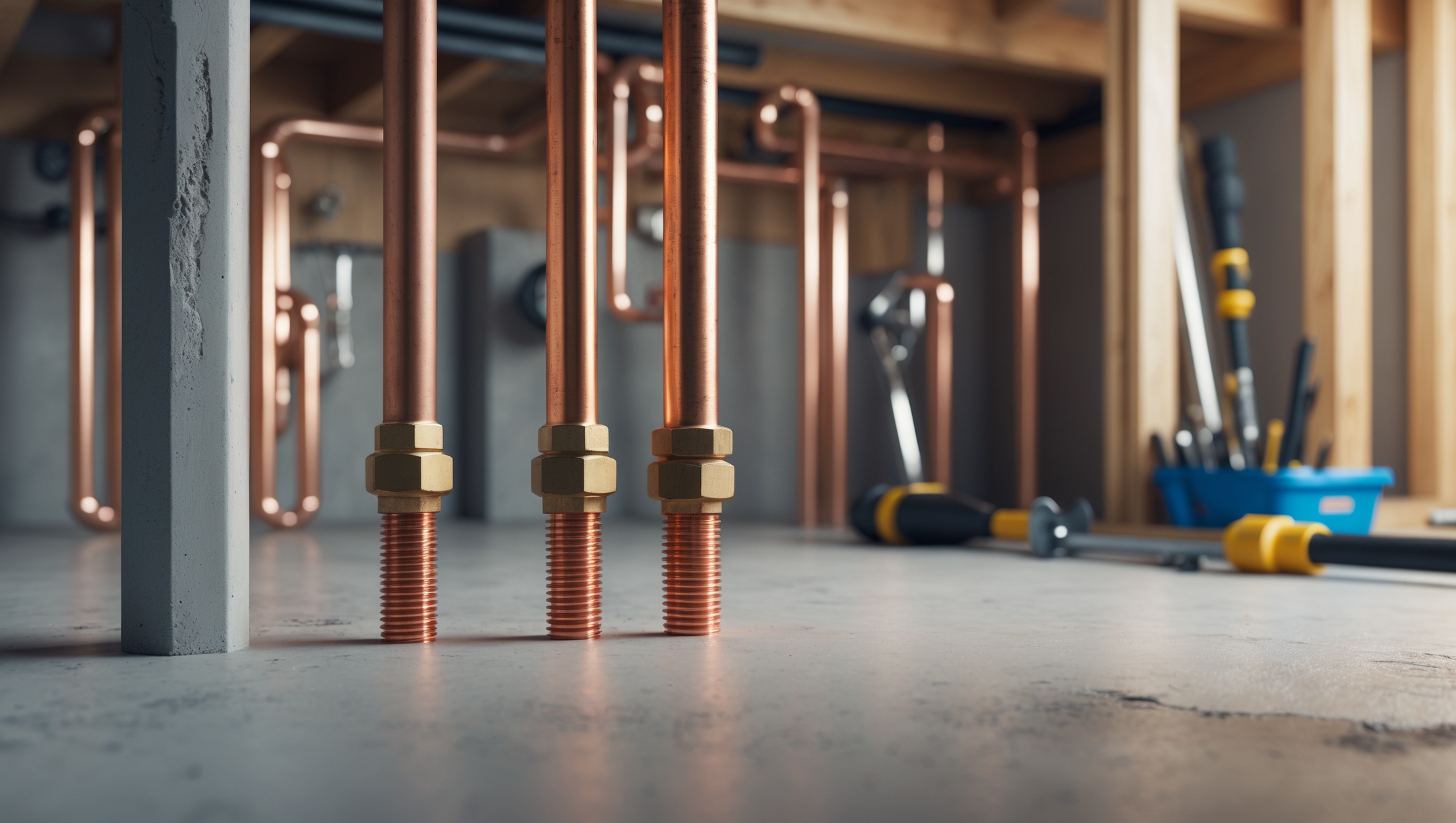

Choosing the Ideal Space: Garage, Basement, or Shed?

Assessing Available Areas

The first step is to evaluate where your plumbing workshop will live. Consider the following options:

- Garage: Offers ample space, good ventilation, and easy access to water lines. Ideal for larger projects and tool storage.

- Basement: Often quieter and separate from living spaces. Moisture control and ventilation are critical concerns here.

- Outdoor Shed: Great for keeping messes out of the house, but may lack climate control and security. Ensure it’s weatherproof and has safe power access.

Key considerations include proximity to water sources, electrical outlets, lighting, and how the space’s temperature and humidity might affect tools and materials.

Space Requirements

For basic plumbing projects, a 6’x8’ area can suffice, but more room is always better. Allow at least 3’ of clear space around your main workbench for movement and safe tool handling. If you plan on cutting pipe or working with large assemblies, a larger footprint (10’x12’ or more) is optimal.

Workshop Layout: Planning for Productivity and Safety

Work Zones

Divide your workshop into distinct zones for maximum efficiency:

- Work Area: Main bench for assembly, repairs, and small projects.

- Cutting & Soldering Zone: Dedicated spot for pipe cutting, threading, soldering, and welding, with fire-safe materials and ventilation.

- Storage Zone: Racks, shelves, and bins for tools, fittings, and consumables.

- Cleaning Area: Utility sink or cleaning station for washing tools and hands.

Workflow Optimization

Arrange zones in a logical sequence: material storage near the entrance, main workbench centrally located, hazardous activities (like soldering) positioned away from flammable materials and easy-to-access exits. Keep high-use tools within arm’s reach of the workbench, and reserve overhead or high shelves for seasonal or rarely used items.

Essential Workbench and Surface Considerations

Workbench Features

Your workbench is the heart of the workshop. Select or build one that is:

- Sturdy enough for heavy work (solid wood or steel frame recommended).

- At least 36” deep and 60” wide for comfortable plumbing assembly.

- Height-adjustable, or at a comfortable working height (typically 34-38” for most adults).

- Equipped with a heavy-duty vise (minimum 4” jaw width), ideally pipe-specific.

Surface Materials

Choose a bench top that resists water, chemicals, and heat—marine plywood with a polyurethane coating, stainless steel, or heavy-duty laminate are all excellent choices. Avoid raw MDF or particleboard, which will quickly degrade in a plumbing environment.

Tool Storage: Keeping Everything in Reach and in Order

Wall-Mounted Solutions

Wall space is prime real estate in a plumbing workshop. Use:

- Pegboards: Hang wrenches, pliers, and frequently used hand tools for instant visibility and access.

- Magnetic Strips: Perfect for holding small metal tools like screwdrivers and snips.

- Wall Racks: Store pipe sections, levels, and long-handled tools off the floor.

Drawers, Bins, and Cabinets

- Drawer Units: Organize small parts (washers, nuts, O-rings) with labeled dividers.

- Clear Bins: Use stackable, see-through bins for fittings, valves, and pipe connectors.

- Lockable Cabinets: Store chemicals, adhesives, or expensive tools securely.

Mobile Toolboxes and Caddies

For jobs around the house or offsite, a well-stocked rolling toolbox or portable caddy saves time and prevents tool loss. Keep these loaded with the essentials, and restock after each use.

Pipe and Material Storage

Piping Organization

Pipe sections and tubing can quickly become tangled and hazardous. Install horizontal wall racks, ceiling-mounted pipe hangers, or vertical floor racks to separate copper, PEX, PVC, and steel pipe. Label sections by diameter and type.

Consumables and Spare Parts

Set up divided bins for pipe fittings, connectors, fasteners, gaskets, and joint compounds. Keep a running inventory, and rotate older stock to the front to avoid expired materials (especially sealants and adhesives).

Lighting, Power, and Ventilation: Creating a Safe Work Environment

Lighting

Effective lighting is non-negotiable. Overhead LED shop lights provide bright, energy-efficient illumination. Add task lighting at the bench and in shadow-prone corners. Position lights to minimize glare and avoid casting shadows on your work area.

Electrical Safety

- Install ground-fault circuit interrupter (GFCI) outlets to reduce shock risk near water sources.

- Use heavy-duty extension cords and avoid daisy-chaining power strips.

- Keep cables off the floor to prevent tripping and water contact.

Ventilation

Many plumbing tasks produce fumes or dust—soldering, using PVC cement, or cutting metal pipe. Install a window fan, exhaust vent, or portable air purifier. In basements, a dehumidifier helps prevent mold and tool rust.

Organizing for Efficiency: Workflow, Labels, and Maintenance

Labeling and Inventory

- Label every drawer, bin, and shelf with contents and, if needed, part numbers.

- Post a laminated quick-reference chart for pipe sizes, fitting types, and thread standards above your bench.

- Keep a digital or paper inventory to track tool and material usage.

Routine Cleaning and Upkeep

- Wipe down benches and tools after each session to prevent corrosion and buildup.

- Sharpen cutting tools and oil moving parts monthly.

- Dispose of hazardous waste (solvents, old pipes) in accordance with local regulations.

Safety Essentials: Fire, Chemical, and Injury Prevention

Fire Safety

- Mount a Class B/C fire extinguisher within easy reach.

- Keep a fire blanket near the soldering/cutting zone.

- Store flammable liquids in a dedicated, ventilated cabinet.

Chemical Handling

- Use gloves, goggles, and, if needed, a respirator when handling solvents, flux, or pipe dope.

- Store chemicals in original containers with labels intact.

- Post Material Safety Data Sheets (MSDS) for all hazardous substances.

Personal Protective Equipment (PPE)

- Stock up on safety glasses, work gloves, and hearing protection.

- Wear steel-toed boots for heavy work and when handling large pipes.

- Have a fully stocked first aid kit and eyewash station available.

Noise, Dust, and Waste Management

Controlling Noise

Plumbing workshops can get loud—pipe cutting, hammering, and power tools all contribute. Use rubber mats to dampen noise, install soundproofing panels if needed, and always wear hearing protection during loud activities.

Dust and Debris Collection

Install a shop vacuum with HEPA filters or a wall-mounted dust collector near the cutting area. Sweep floors regularly, and keep walkways clear of debris to prevent slips and falls.

Waste Disposal

- Separate metal, plastic, and hazardous waste. Recycle scrap metal and unused pipe where possible.

- Dispose of solder, adhesives, and chemical containers according to local hazardous waste rules.

Upgrading Your Workshop: Advanced Features and Extras

Plumbing-Specific Additions

- Pipe Threading Station: Mount a manual or powered pipe threader for custom lengths and fittings.

- Test Bench: Set up a bench with pressure gauges and water connections for leak-testing assemblies.

- Dedicated Water Supply: If possible, install a utility sink or hose bib for cleaning and testing.

Technology and Organization Tools

- Install a wall-mounted tablet or computer for viewing digital manuals, inventory management, or video tutorials.

- Use barcode or QR code systems for quick inventory checks.

- Integrate smart lighting or voice-activated switches for convenience.

Common Mistakes to Avoid When Setting Up Your Plumbing Workshop

- Underestimating Space Needs: Crowded workspaces lead to clutter and accidents.

- Neglecting Safety: Skipping PPE or fire protection can have serious consequences.

- Poor Lighting: Insufficient lighting causes mistakes and increases injury risk.

- Lack of Ventilation: Fumes from solvents and solder can be hazardous without proper airflow.

- Improper Tool Storage: Tools left on benches or floors are easily damaged or lost.

- Ignoring Moisture Control: Failing to manage humidity will rust tools and degrade materials.

Conclusion: Building a Workshop that Grows with You

Establishing a dedicated plumbing workshop at home is an investment in your skills, safety, and project satisfaction. By carefully selecting your space, organizing for efficiency, and implementing robust safety measures, you’ll create a workshop that empowers you to tackle everything from minor repairs to major installations with confidence. Remember, the ideal setup isn’t static—it evolves alongside your needs and ambitions. As you gain experience, you may find new tools or techniques that demand extra storage or specialized work zones. Stay proactive: keep your space clean, your inventory up-to-date, and your safety practices uncompromising. A well-maintained workshop isn’t just a convenience—it’s a foundation for quality workmanship and peace of mind. Whether you’re fixing a leaky faucet, building a custom shower, or just learning the ropes, the right workshop makes every plumbing challenge more manageable and rewarding. Start small if you must, but plan with growth in mind. Your future self—and your plumbing projects—will thank you.

Andrew Clark

I have a basement that tends to get pretty damp and I’m worried about moisture affecting my plumbing tools. What are some effective ways to control humidity and prevent rust in a basement workshop?