Introduction: Why DIY Plumbing Mistakes Happen—and What This Guide Offers

Plumbing is one of the most common areas where homeowners attempt DIY fixes. With countless online tutorials and easy-to-find tools, it’s tempting to handle leaks, clogs, or even bigger projects yourself. But even the most enthusiastic beginners can fall prey to simple mistakes—ones that can lead to costly repairs, water damage, or even safety hazards down the line. Understanding the most frequent DIY plumbing errors, and how to sidestep them, is essential if you want to protect your home, save money, and gain confidence in your repair skills.

This comprehensive guide is tailored specifically for those new to plumbing. We’ll cover the most common missteps made during DIY plumbing projects, explain why they happen, and provide clear, actionable advice to avoid them. Expect practical tips rooted in real-world experience, straightforward safety recommendations, and product suggestions where appropriate. Whether you’re fixing a dripping faucet, replacing a section of pipe, or just want to be prepared for the next minor emergency, this guide will help you do it right the first time.

The Most Common DIY Plumbing Mistakes

1. Over-Tightening Connections

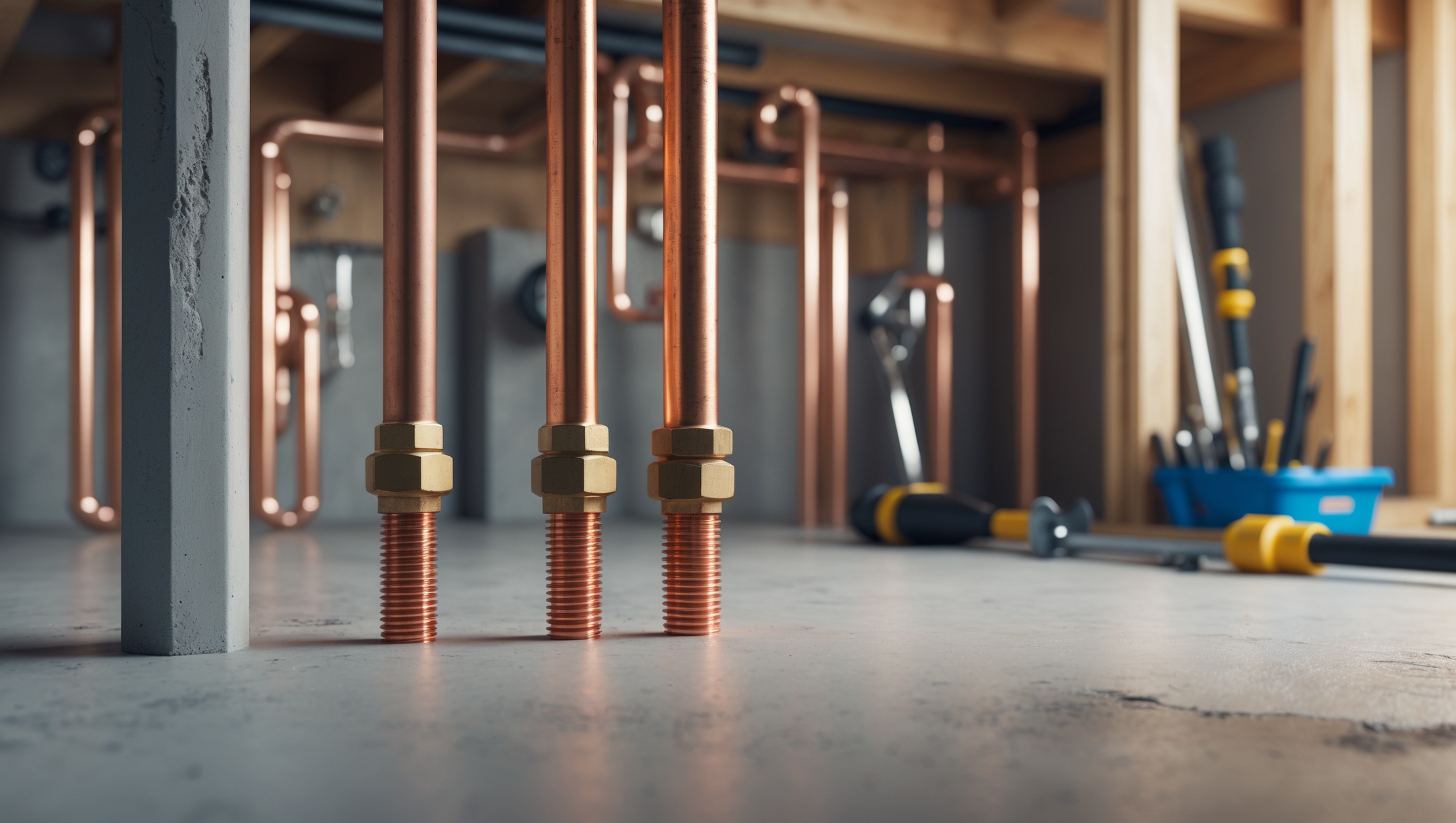

One of the most frequent errors beginners make is over-tightening pipe fittings, supply lines, or valve connections. The instinct to “make sure it’s secure” can backfire: excessive force can strip threads, crack fittings, or damage seals. This mistake often leads to slow leaks or catastrophic breaks—sometimes days or weeks after you thought the job was finished.

- How to Avoid: Use hand-tightening plus an additional quarter-turn with a wrench. Stop when you feel resistance; never force further.

- Pro Tip: For compression fittings, overtightening can actually deform the ferrule, causing leaks. Tighten just until snug.

2. Using the Wrong Tools (or No Tools at All)

Grabbing whatever’s handy—like pliers or an adjustable wrench—can cause more harm than good. Tools not designed for plumbing can slip, round off fasteners, or damage fixtures. In some cases, using no tools at all (such as hand-tightening plastic nuts) will result in loose, leaky connections.

- How to Avoid: Invest in a basic set of plumbing tools: a pipe wrench, basin wrench, channel locks, and Teflon tape. For plastic fittings, use hand tools only and never overtighten.

- Pro Tip: Always use the correct size wrench for compression and supply line fittings to prevent rounding or stripping.

3. Ignoring Water Shutoff Valves

Attempting repairs without shutting off the water supply is a recipe for disaster. Even a small drip can become a gusher when a pipe is cut or a fitting is removed, leading to flooding and water damage.

- How to Avoid: Always locate and turn off the nearest shutoff valve before starting any plumbing work. For whole-house projects, use the main water shutoff.

- Pro Tip: Test the water line by turning on the faucet after shutting off the valve to ensure no water is flowing.

4. Using the Wrong Materials

Not all pipes, fittings, or sealants are interchangeable. Using incompatible materials—like connecting copper directly to galvanized steel without a dielectric union—can cause corrosion, leaks, or even health hazards.

- How to Avoid: Match materials carefully. Use only approved fittings for your pipe type (PVC, PEX, copper, etc.). When in doubt, consult manufacturer guidelines or a pro.

- Pro Tip: Always use plumber’s tape (PTFE/Teflon tape) on threaded metal connections, and pipe dope on metal-to-metal or gas fittings only.

5. Skipping the Drain Trap

Some beginners mistakenly remove or fail to reinstall the P-trap (the U-shaped pipe under sinks) during repairs. The P-trap is essential for preventing sewer gases from entering your home and blocking debris from clogging deeper pipes.

- How to Avoid: Always reinstall the P-trap after repairs. Inspect the washers and connections for leaks before finishing.

- Pro Tip: Keep a bucket underneath when disassembling the P-trap to catch residual water and debris.

6. Misusing Chemical Drain Cleaners

Chemical drain cleaners seem like a quick fix for clogs, but overuse—or using them incorrectly—can damage pipes, especially older metal or PVC systems. They may also fail to clear the clog, leaving behind caustic residue that’s hazardous to handle.

- How to Avoid: Use mechanical methods first, such as a plunger or drain snake. Reserve chemical cleaners for last resorts, and always follow the manufacturer’s instructions exactly.

- Pro Tip: If you’ve used a chemical cleaner, warn any plumber who works on the same line afterward to prevent chemical burns.

7. Failing to Slope Drain Pipes Properly

When replacing or extending drain pipes, beginners sometimes install them level or even sloping in the wrong direction. Proper slope (typically 1/4 inch per foot) is essential for waste to flow by gravity; too little or too much slope can cause blockages or slow drainage.

- How to Avoid: Use a level to ensure the correct slope when installing horizontal drain lines.

- Pro Tip: Secure pipes with hangers or brackets every 4 feet for horizontal runs to maintain consistent slope.

8. Forgetting to Test for Leaks

Completing a repair and putting away your tools without checking for leaks is a common oversight. Even small, slow leaks can cause significant water damage over time.

- How to Avoid: Once you’ve finished, turn the water back on gradually and inspect every connection, joint, and fitting for drips.

- Pro Tip: Use a dry paper towel to check for tiny leaks along seams and under fittings.

9. Poor Pipe Support and Securing

Pipes that aren’t properly supported can sag or vibrate, causing noise (water hammer), leaks at joints, or even breaks due to stress over time.

- How to Avoid: Use appropriate pipe supports and hangers, especially for longer runs. Don’t rely on friction or tight spaces to hold pipes in place.

- Pro Tip: For copper pipes, use cushioned supports to prevent noise and wear from expansion and contraction.

10. Not Checking Local Codes

Even small plumbing jobs are subject to local codes. Failing to comply can mean failed inspections, fines, or the need for expensive rework if you sell your home.

- How to Avoid: Before starting any significant project, check your city or county’s plumbing code. Some areas restrict DIY work beyond basic repairs.

- Pro Tip: Permits may be required for water heater installs, moving supply or drain lines, or adding fixtures. When in doubt, call your building department.

Essential Safety Tips for DIY Plumbers

Wear Proper Protective Gear

Always wear gloves, safety glasses, and old clothes. Plumbing repairs can expose you to sharp edges, chemicals, and dirty water.

Watch Out for Electricity

Never work on plumbing near electrical outlets, switches, or appliances without first shutting off the power. Water and electricity are a dangerous combination.

Ventilate When Using Chemicals

If you must use chemical cleaners or adhesives, open windows and doors to ensure good airflow. Wear a mask if fumes are strong.

Know Your Limits

If you’re unsure about a repair, or if a situation seems unsafe, it’s always wise to consult a professional plumber. Don’t risk injury or property damage.

Step-by-Step: Fixing a Leaky Sink Trap (A Beginner’s Tutorial)

Tools and Materials Needed

- Channel-type pliers or adjustable wrench

- Replacement washers or P-trap kit (if needed)

- Bucket

- Rags or towels

- Plumber’s tape (for threaded connections)

Step 1: Turn Off the Water

Locate the shutoff valves under your sink and turn them clockwise until they stop. Open the faucet to relieve pressure and drain remaining water.

Step 2: Place a Bucket Under the Trap

Slide a bucket beneath the P-trap to catch any water that spills when you disconnect the pipes.

Step 3: Loosen the Slip Nuts

Using your hands or pliers, loosen the slip nuts on either side of the P-trap. Carefully remove the trap and dump out any water and debris.

Step 4: Inspect and Clean the Trap

Look for cracks or wear. If the washers are worn or missing, replace them. Clean the inside of the trap thoroughly.

Step 5: Reassemble with New Washers (If Needed)

Reinstall the trap, ensuring washers are seated correctly. Tighten the slip nuts by hand, then give a gentle extra turn with pliers—do not overtighten.

Step 6: Test for Leaks

Turn the water back on and run it for at least 30 seconds. Check all joints for leaks. If you see drips, gently tighten the connections until they stop.

Bonus: Quick Reference Checklist for DIY Plumbing Success

- Plan the repair—know what parts and tools you need before starting.

- Always shut off water and, if necessary, power.

- Use the right tool for every connection.

- Double-check all fittings and washers before reassembly.

- Test thoroughly for leaks after finishing a job.

- Clean up and properly dispose of any waste or old parts.

- Know when to call a professional—never guess with gas lines or major water leaks.

Conclusion: Mastering DIY Plumbing—Confidence and Caution Go Hand in Hand

Tackling your own plumbing repairs can be incredibly rewarding, saving you money and expanding your home maintenance skillset. However, as we’ve explored in this guide, beginner mistakes are common—and often preventable with the right preparation and knowledge. By understanding the most frequent pitfalls, from over-tightening fittings to ignoring safety basics, you equip yourself to handle repairs more safely and effectively.

Remember, successful DIY plumbing is about patience, attention to detail, and respecting the unique requirements of pipes, fittings, and fixtures. Always double-check your work, never skip safety steps, and don’t hesitate to research or ask questions before starting a project. With each successful fix, your confidence will grow—just be sure to recognize your limits and call in a professional when the situation calls for it.

Above all, treat every plumbing project as an opportunity to learn. Mistakes happen, but with the right approach, they’ll become fewer and less costly. Armed with this knowledge and a commitment to safe, careful work, you’re well on your way to becoming your household’s trusted plumbing expert.

Patricia Lewis

When you say to go hand-tight and then a quarter turn with a wrench, does that apply to all types of plumbing connections (like PVC, copper, or supply lines), or are there exceptions I should know about?